The Importance of Quality Control in Mining Drill Consumables

In the mining industry, where precision and efficiency are of great importance, the quality of equipment and consumables plays a crucial role in the success of operations. When it comes to mining drill consumables, maintaining stringent quality control measures are paramount. From drill bits to rods and other essential components, ensuring the highest level of quality in these consumables can significantly impact drilling performance, productivity, and ultimately, the bottom line.

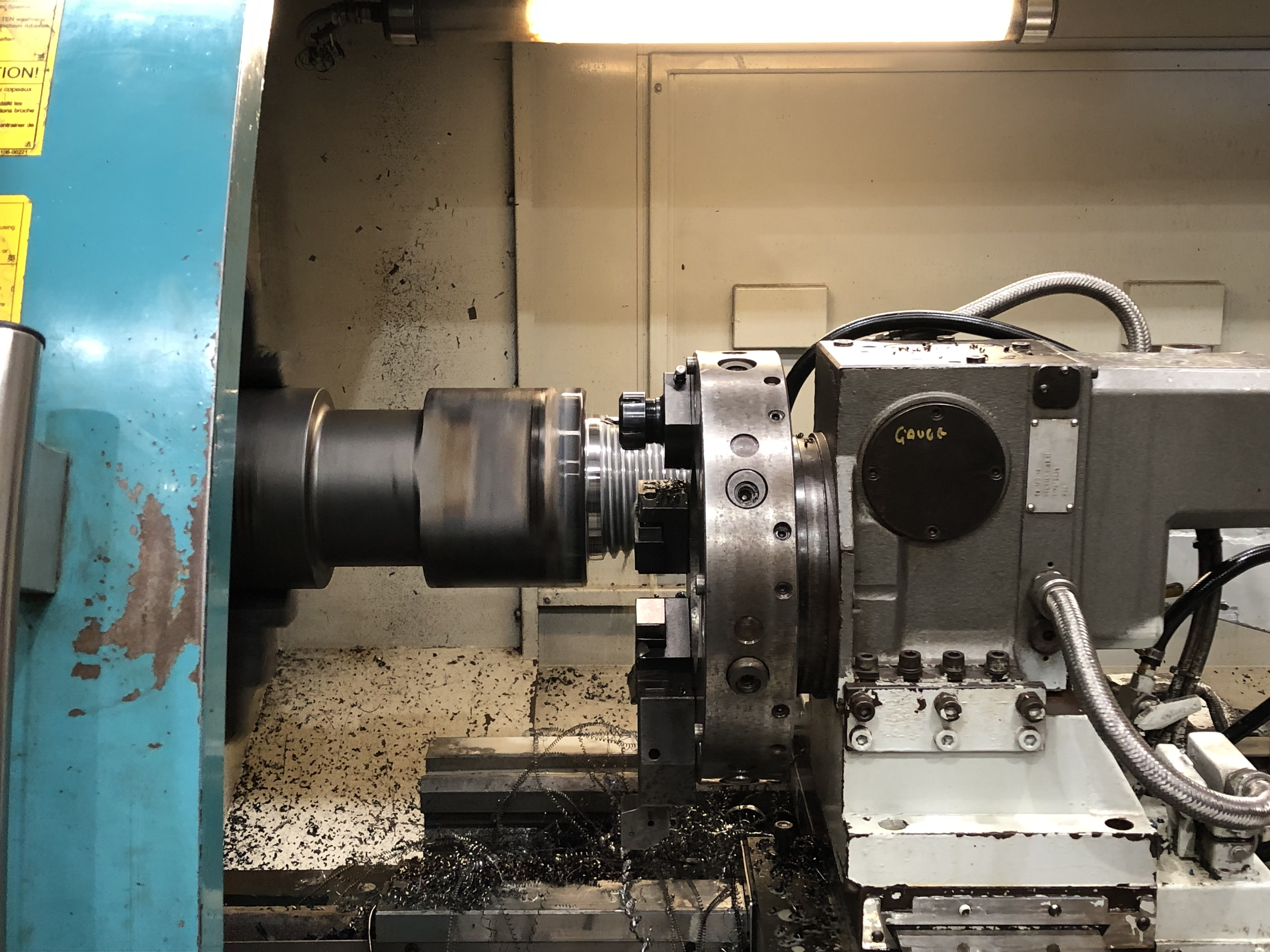

At AMS we are proud of our commitment to maintaining a high standard of quality control when manufacturing products which is achieved with our ISO 9001 certification.

In this article, we will explore the significance of quality control in mining drill consumables and how it contributes to operational excellence.

- Reliability and Performance: Quality control measures are designed to ensure that mining drill consumables meet rigorous standards for reliability and performance. By maintaining consistent quality in the manufacturing process, consumables are less likely to fail prematurely or underperform. Reliability is crucial in mining operations, as unexpected failures can lead to costly downtime, delays, and compromised safety. High-quality drill consumables deliver reliable performance, allowing mining companies to optimise their operations and achieve their production targets efficiently.

- Durability and Longevity: Mining drill consumables are subjected to harsh and demanding conditions, including abrasive rock formations, extreme temperatures, and high-pressure drilling environments. Quality control ensures that these consumables are manufactured using durable materials, such as tungsten carbide or diamond, that can withstand these challenging conditions. Consumables with superior durability and longevity reduce the frequency of replacements, minimising downtime and maintenance costs. Investing in high-quality consumables results in long-term cost savings and enhanced operational efficiency.

- Precision and Accuracy: Accurate drilling is crucial in mining operations to achieve desired outcomes, such as specific hole sizes, precise depths, or targeted mineral extraction. Poor-quality drill consumables can lead to inconsistencies in hole dimensions, affecting the overall accuracy of the drilling process. Quality control measures focus on maintaining precise manufacturing tolerances, ensuring that consumables meet the required specifications. This precision and accuracy contribute to improved drilling results, better fragmentation, and optimised blasting patterns, ultimately maximising productivity and resource recovery.

- Safety and Risk Mitigation: Mining operations are inherently risky, and the quality of drill consumables can impact safety. Substandard consumables may fail under high-stress conditions, posing risks to the drill operators and other personnel on-site. Quality control processes identify and eliminate manufacturing defects, ensuring that the consumables meet stringent safety standards. By using high-quality drill consumables, mining companies can mitigate risks associated with equipment failure, reducing the likelihood of accidents, injuries, and potential environmental impacts.

- Supplier Reputation and Collaboration: Maintaining quality control in mining drill consumables involves collaboration with reputable suppliers who prioritise quality in their manufacturing processes. Choosing reliable suppliers with a strong track record in quality control ensures a consistent supply of high-quality consumables. Collaborating with these suppliers can also provide access to expertise, technical support, and customised solutions tailored to specific drilling requirements. Building strong relationships with reputable suppliers contributes to a sustainable supply chain and fosters a culture of continuous improvement.

- Compliance with Industry Standards: The mining industry is governed by strict regulations and industry standards that aim to protect workers, the environment, and surrounding communities. Quality control processes in the manufacturing of drill consumables ensure compliance with these standards. By using consumables that adhere to the prescribed regulations, mining companies demonstrate their commitment to responsible and sustainable operations. Compliance with industry standards also enhances the reputation of the company, fostering trust among stakeholders and investors.

Maintaining rigorous quality control in mining drill consumables is vital for achieving operational excellence in the mining industry. By prioritising reliability, durability, precision, and safety, high-quality consumables optimise drilling performance, minimise downtime, and reduce overall costs. Collaborating with reputable suppliers and adhering to industry standards further reinforces the commitment to excellence.